|

|

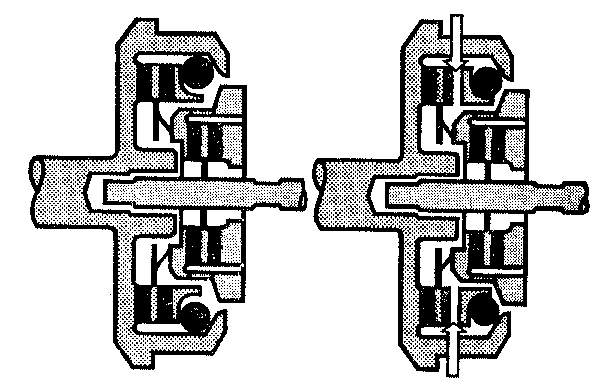

| The Olymat (Saxomat) clutch is a combination of two single dry plate clutches: one is operated by centrifugal force and utilises a bronze friction material and another is a normal type with asbestos material and is operated by a release bearing, a clutch lever and a vacuum actuator. The illustration to the left shows the high-rpm situation vhere the centrifugal clutch is engaged. The illustration to the right shows the low-rpm situation where the centrifugal clutch is released. |

|

|

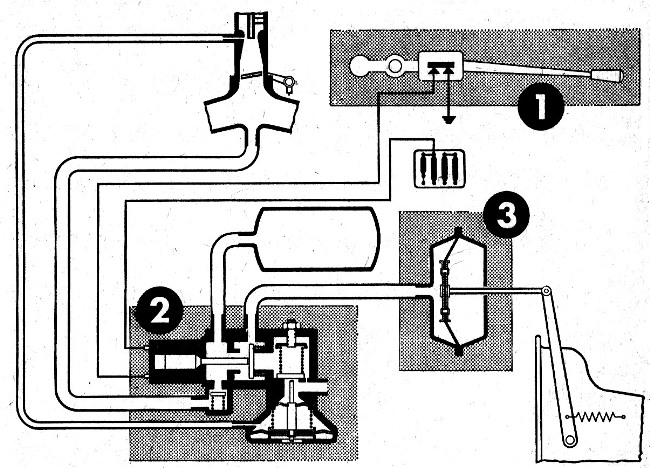

| The purpose of the clutch control system is to release the clutch whenever the gearlever (1) is operated and reengage the clutch, when a new gear has been selected, and the accelerator pedal is depressed. Vacuum is supplied from the intake manifold and stored in a reservoir. When the gearlever is touched electric current is supplied to the solenoid in the controlvalve (2). Vacuum is transferred to the vacuum diaphragm actuator (3) which pulls the clutch lever and releases the clutch. The diaphragm-valve-system at the right end of the control valve (2) ensures a controlled vacuum release and thereby a soft reengagement of the clutch. The thin hose connection to the upper part of the carburettor signals a hard depressed accelerator which hastens the clutch take-up. |